Hrushikesh Shah

LEED AP BD+C

Fabricating Revit

Guidance of Sho Sugimoto and John Michaels

Summer Internship, R3A, Pittsburgh

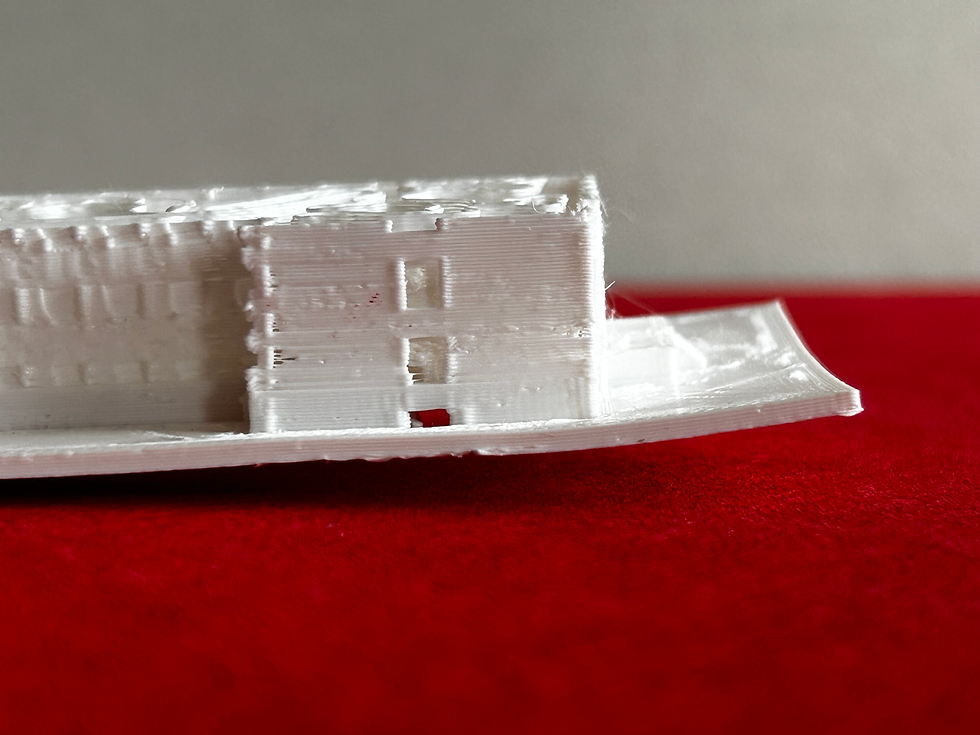

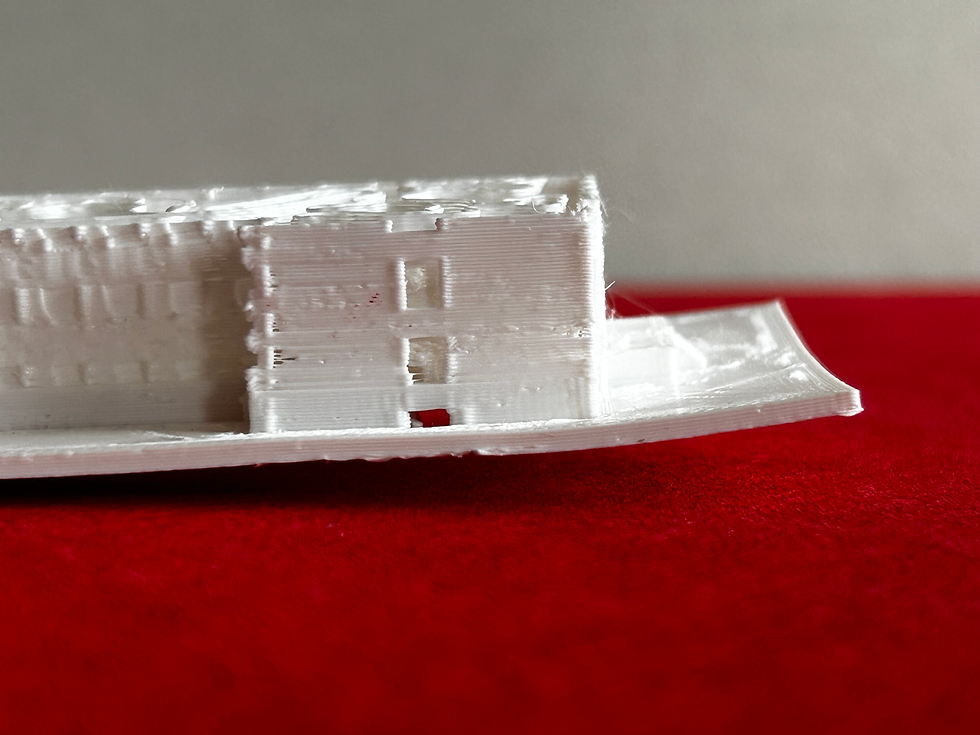

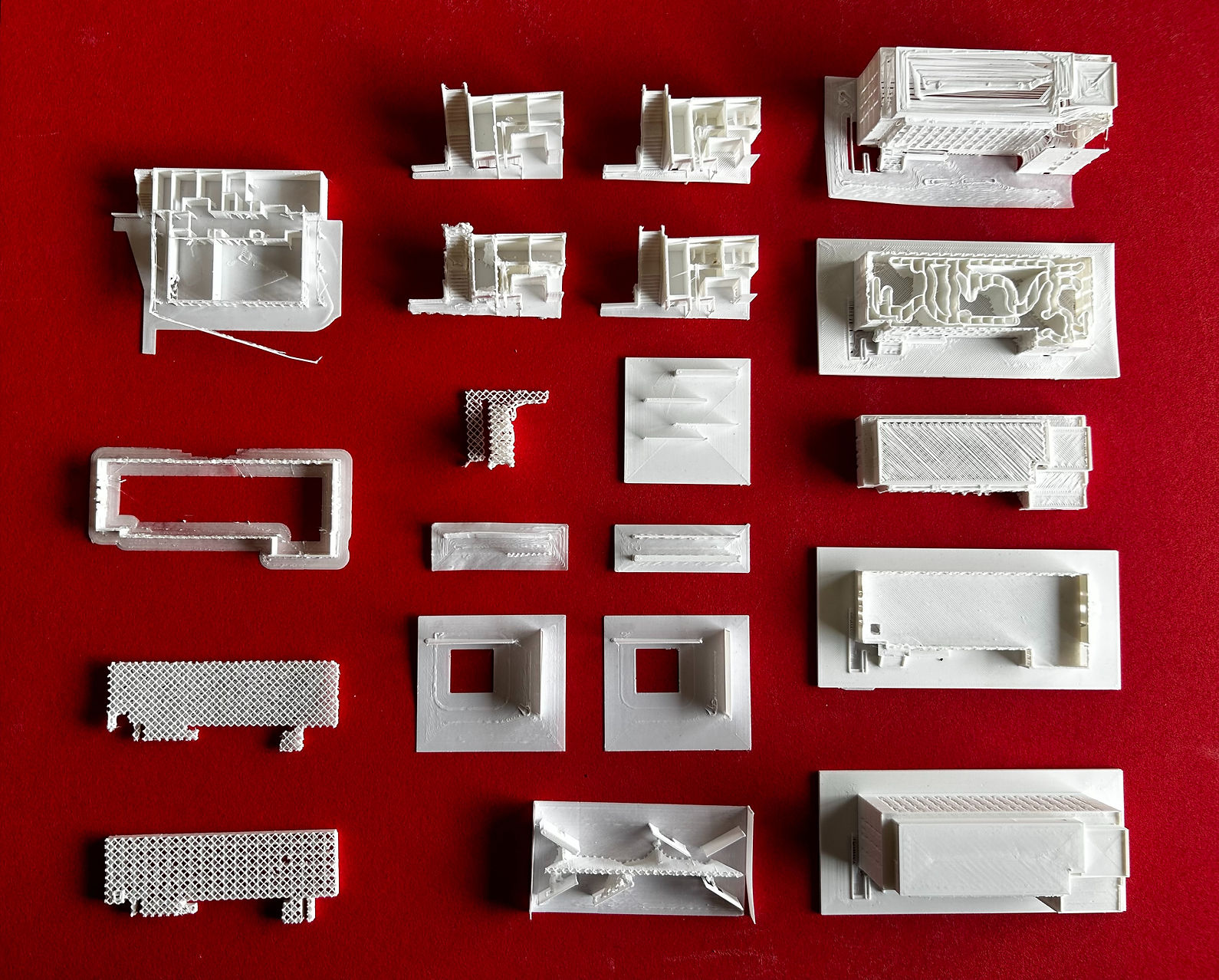

Revit is a fabulous tool for co-ordination, design and construction documentation but what if the same model could be directly 3d printed with reduction of details based on the required scale of the 3d model. The former practice was to recreate the Revit model in Rhino or SketchUp before slicing it in Ultimaker Cura. This former workflow took longer time and details were lost in translation. The new workflow enabled heavy Revit models to sequentially reduce unnecessary details to make it ready for direct 3d printing. The second part of this project was to fix the settings templates to be used according to the required quality and speed of time. Rigorous experimentation was done to understand the minimum tolerances of 3d printers. Again, Miro board was used to systematically understand the settings, workflows and document progress. The project ultimately resulted in a 66 page document of the entire workflow including trouble shooting.

Workflow Document Preview

Workflow Document Thumbnails

Understanding the 3d Printing technology